Does the greenhouse gas methodology hinder reuse?

HVAC - The hidden climate giant

Glynitveien 33

Photo: Höegh Eiendom

However, the method for calculating greenhouse gas emissions from reuse is still unclear and creates uncertainty about how much savings reuse can contribute.

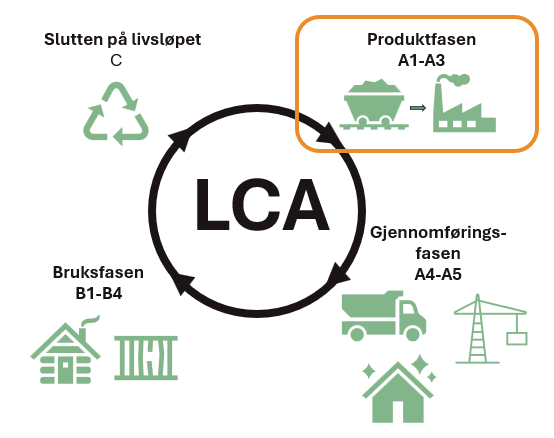

Reuse in a life cycle perspective

There is a clear advantage to installing a reused product, rather than a newly manufactured product, when looking at emissions from production in isolation, i.e. product phase A1-A3. The picture becomes more complex when we consider the entire life cycle and ambiguity in the methodology can become a barrier to reuse.

Grønn VVS's Glynitveien 33 model project aimed to achieve 100% reuse during the interior renovation of the premises. The work resulted in over 70% circularity (preserved, reuse, surplus and recycling) for the ventilation delivery and a greenhouse gas reduction of close to 40% in the life cycle phase A1-A3. However, calculations for the entire life cycle showed that greenhouse gas reductions could vary from 0 to 30%, depending on the methodology used.

Methodological uncertainties

There are several methodological challenges associated with measuring the full environmental impact of reuse. Some of the most central issues include:

- Distribution of production emissions between “donor building” and “recipient building” (A1-A3):

- Which production emissions should be allocated to a reused product

- How are emissions related to processing, cutting and adapting the reused product allocated?

- Residual life of reused products (From A1-A3 to B4):

- How long is the residual life of the reused product?

This significantly affects the need for the number of replacements and thus the environmental impact.

- How long is the residual life of the reused product?

- Choice of replacement scenario (B4):

What happens when a product is replaced is also an important factor. Will the product be replaced by a newly manufactured product, a new reused product according to the circular strategy, or will you repair parts of the existing product? The choice here can have a major impact on the total environmental impact.

To understand and maximize the climate benefits of reuse, a thorough analysis of the entire life cycle of the products is required. In the Glynitveien 33 project, Green Plumbing will illustrate both the potential of using recycled products, but also the challenges of different methods for greenhouse gas calculations (Figure 1), such as:

1. Greenhouse gas emissions for the recycled product (A1-A3):

Choice of a conservative calculation (Futurebuilt method) with 20% production emissions allocated to the recycled product (columns 2 and 3) or the "zero emission method" where greenhouse gas emissions are allocated in their entirety to the donor building (columns 4 and 5).

The different methods give a difference of 800 kgCO₂e and 10% on A1-A3 for Glynittveien 33.

2. Remaining life of reusable products (From A1-A3 to B4):

Choice of residual life for the reusable product of 60% or 80% of the original life (R=60% and R=80% respectively on columns 2-5).

The different methods give a difference of up to 1,250 kgCO2e and 10% on B4 for Glynitveien 33.

3. Choice of scenario in the future when replacing (B4):

The future choice to replace the reusable product with newly manufactured products (columns 2 and 4) or continue to replace it with reusable products (columns 3 and 5).

The different methods give a difference of 4,200 kgCO2e and 35% on B4 for Glynitveien 33.

Photo: Multiconsult

Incentives for reuse are the path to a sustainable future

Norway aims to be a pioneer in the development of a green and circular society that makes better use of resources. To move from a linear to a circular construction industry, the methods chosen must provide incentives for choosing reusable products and products suitable for replacement of parts. This is especially important for future scenarios, where uncertainty remains high.

Although reusable products provide clear benefits in the greenhouse gas account in the early life cycle phases (A1 A3), there is a need to develop more precise methods to fully understand and optimize the long-term environmental benefits of reuse. By addressing methodological challenges and developing better tools for life cycle analysis and replacement of parts, we can get a clearer picture of how reuse can contribute to a more sustainable future. This will also provide a basis for creating guidelines and standards that ensure that reuse is always the most environmentally friendly option, even on paper.

We in the industry see a great need for a clear method for calculating greenhouse gas emissions from re-use. We therefore applaud and contribute to the work currently being carried out in the National Knowledge Arena and the guide initiated by the Green Building Alliance. This work is crucial to ensuring that re-use becomes an integral part of Norway's transition to a circular society and a more sustainable future.

Further information about Green HVAC

Green Plumbing is an Innovation Project in the business sector, supported by the Research Council of Norway. The project was carried out in the period September 2021 to March 2025.

Project objectives: Building competence, developing new services and sharing knowledge. Showing the way to a 50% reduction in greenhouse gas emissions from HVAC installations in model projects

The project manager is Multiconsult. Partners in the project are Höegh Eiendom, GK, Armaturjonsson, Swegon, KLP Eiendom and Pipelife. R&D supplier is OsloMet. The reference group consists of VKE and FutureBuilt.