Climate control for the climate´s sake

HVAC - The hidden climate giant

Photo: Thomas Haugersveen

In a new and comprehensive study, it has now been shown that good indoor climate can be achieved with significantly less climate impact. But the relationship between the solutions surprised the researchers.

Initial studies indicated potential

The Green HVAC research project shows that HVAC accounts for 20-40 percent of the greenhouse gas load associated with material use in new buildings. In one of the first applications of Multiconsult's proprietary greenhouse gas tool, different solutions were compared for a small section of an office landscape. The results showed large fixed emissions from materials, and great variation between solution choices. Certain components, such as radiators, appeared particularly emission-intensive. Since the study covered a smaller area, the findings were not necessarily correct for entire buildings, including infrastructure. More research was needed.

A comprehensive study is being created

In order to get answers about what the solutions of the future are, the researchers saw it as necessary to study different solutions more comprehensively, based on a hypothesis that the choice of air conditioning solution has a major impact on greenhouse gas emissions. A separate study was therefore created in collaboration between the research groups Grønn VVS and Hybridene. Various relevant typologies for schools and offices were prepared, which were modeled in Revit and thoroughly simulated in IDA ICE, to form the basis for calculating greenhouse gas emissions from material use, energy use and achieved indoor climate. The work for both building categories, as well as hybrid solutions, will be published in a separate report in 2025, but parts of the main findings for offices are presented here.

Five different air conditioning solutions for offices

The work studied five different typologies in a typical office building:

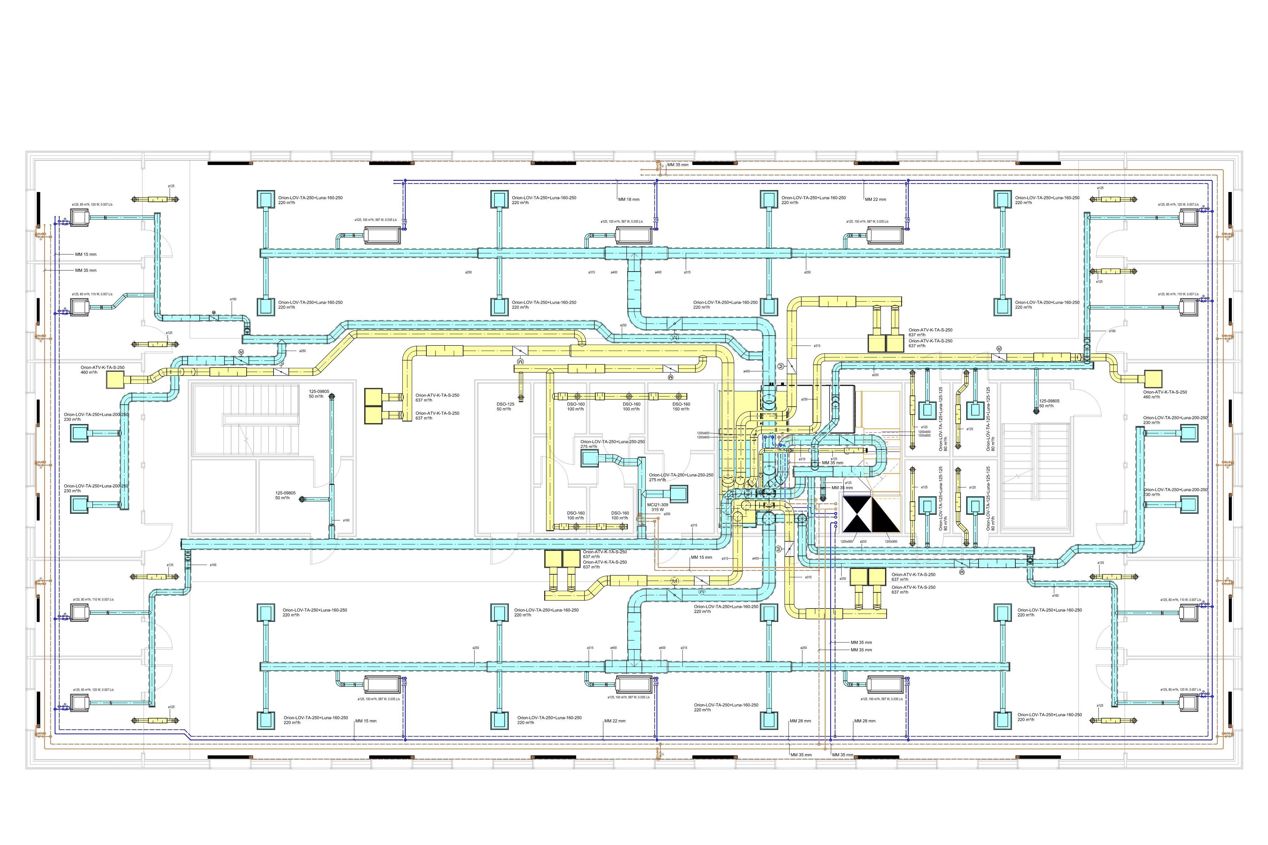

- Mek1: Conventional air conditioning, with 2-pipe chilled beams for cooling and radiators under windows. A historically widely used solution, which is used as a basis for comparison. The solution is shown in Figure 1.

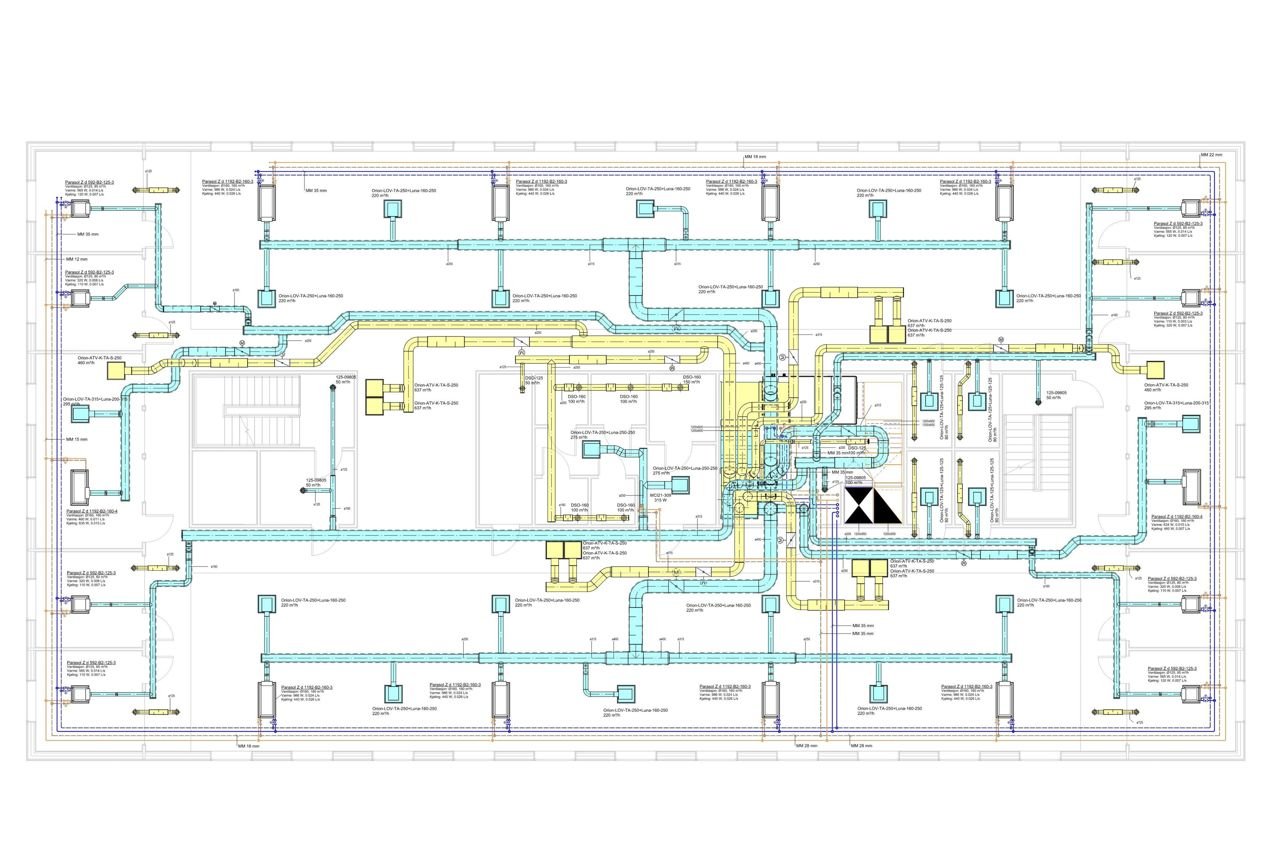

- Mek2: Office machine, with 4-pipe combi-baffles for both cooling and heating. The solution is shown in Figure 2.

- Mek3: Active valves with local electrics, with VAV built into the valves, heating with electric radiant panels and cooling with ventilation air. The solution is shown in Figure 3.

- Mek4: Active valves with underfloor heating and floor cooling, with VAV built into the valves, low-temperature underfloor heating and cooling with high-temperature underfloor cooling. The solution is shown in Figure 4.

- TF: Trimmed displacement, with centrally located displacement valves, low-temperature underfloor heating and cooling with high-temperature underfloor cooling. The solution is shown in Figure 5.

Photo: Multiconsult

Photo: Multiconsult

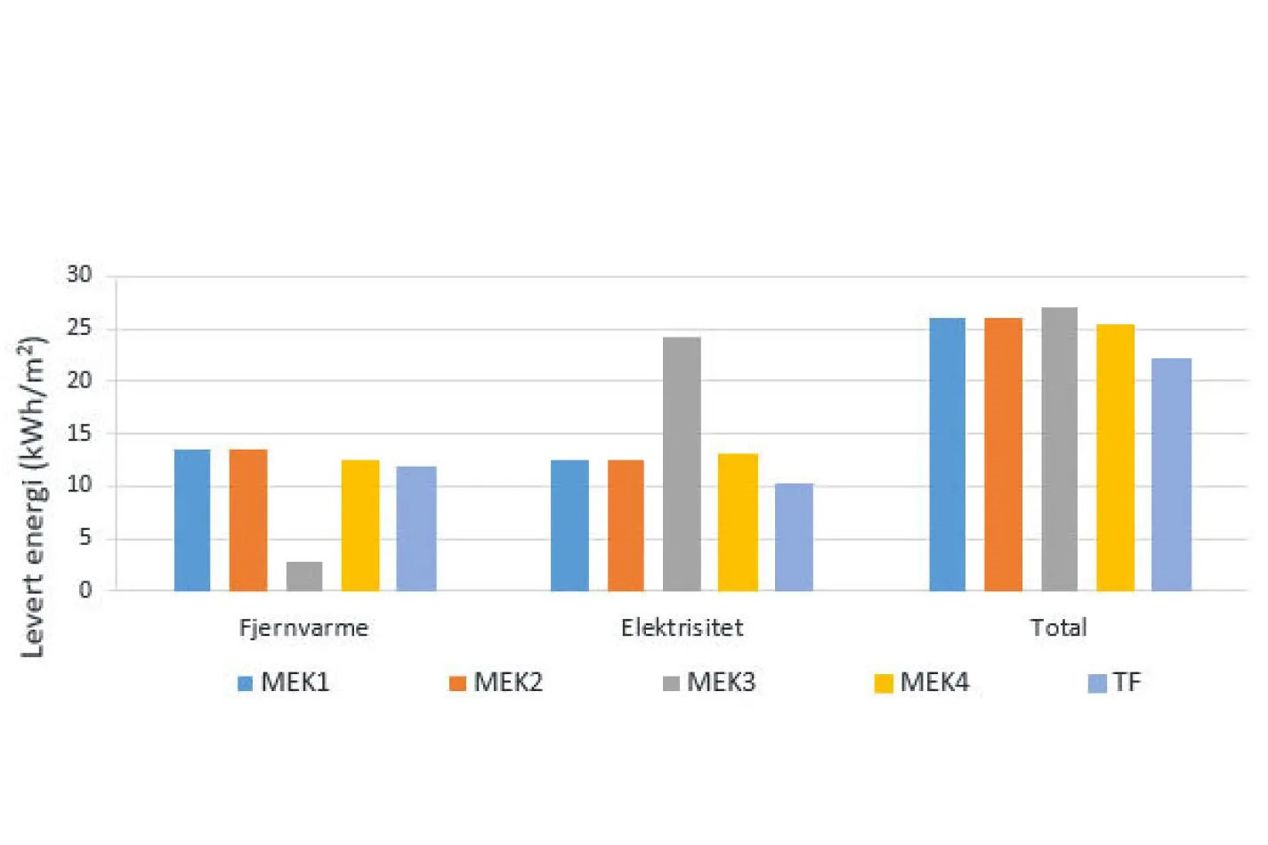

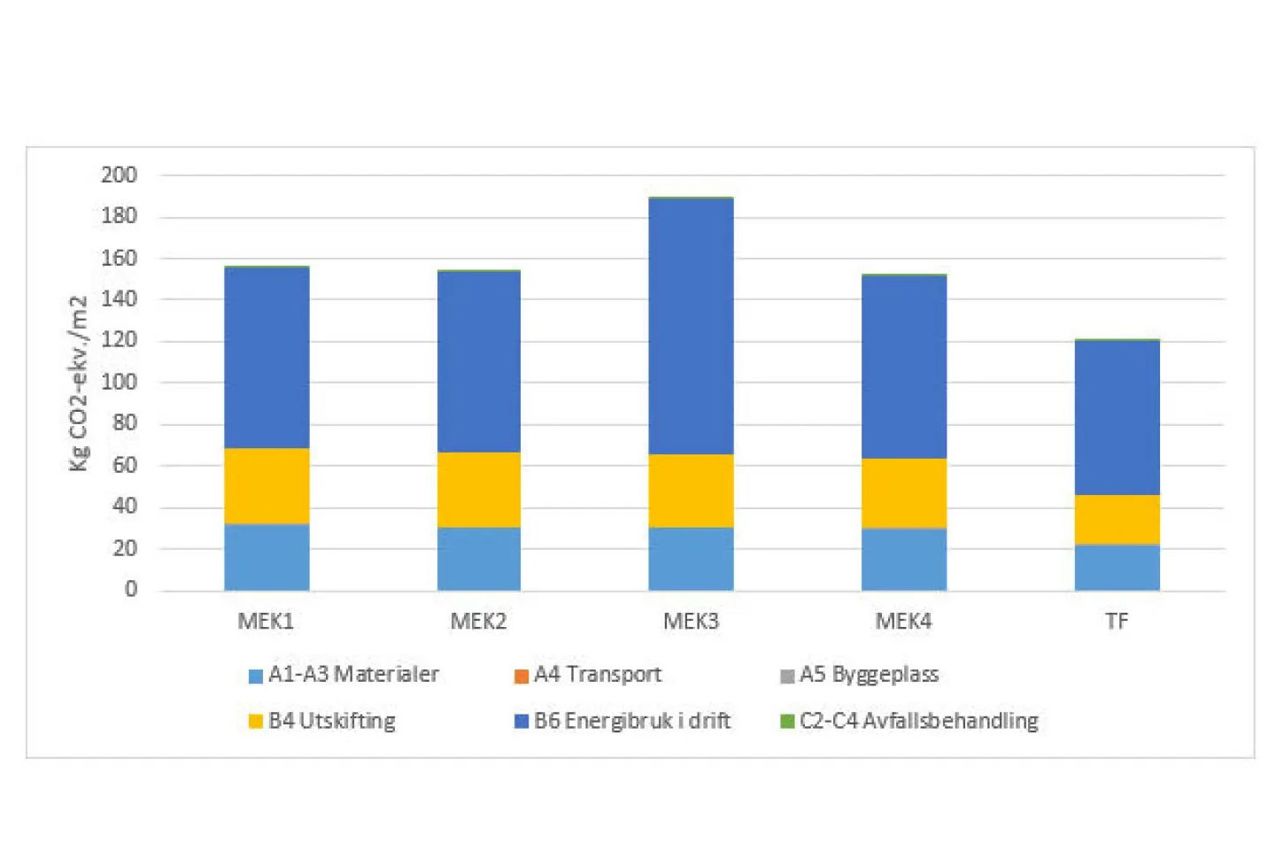

The need for delivered energy to the building is shown in Figure 7. This depends on more factors than net energy demand, for example how efficient the heat and cooling emitters are and the energy supply solution. In the more in-depth report, two different energy supply solutions are used, but here only the results using district heating and a chiller with a dry cooler are presented.

The results for delivered energy show that there is still relatively little difference between MEK1-4, with a tendency for higher energy demand in MEK 3, while TF has the lowest need for delivered energy.

Photo: Multiconsult

Reduced material use provides the fastest emission reduction

During installation, fixed emissions arise that mainly originate from the production of materials, while emissions related to replacement and energy use in the operational phase are future and accumulate over time. Over an analysis period of 50 years, emissions from energy use in operation will constitute a significant proportion of total emissions, but there is greater uncertainty associated with factors that affect future emissions. It is therefore appropriate to prioritize material use, as emissions from this source can be reduced quickly and with greater certainty.

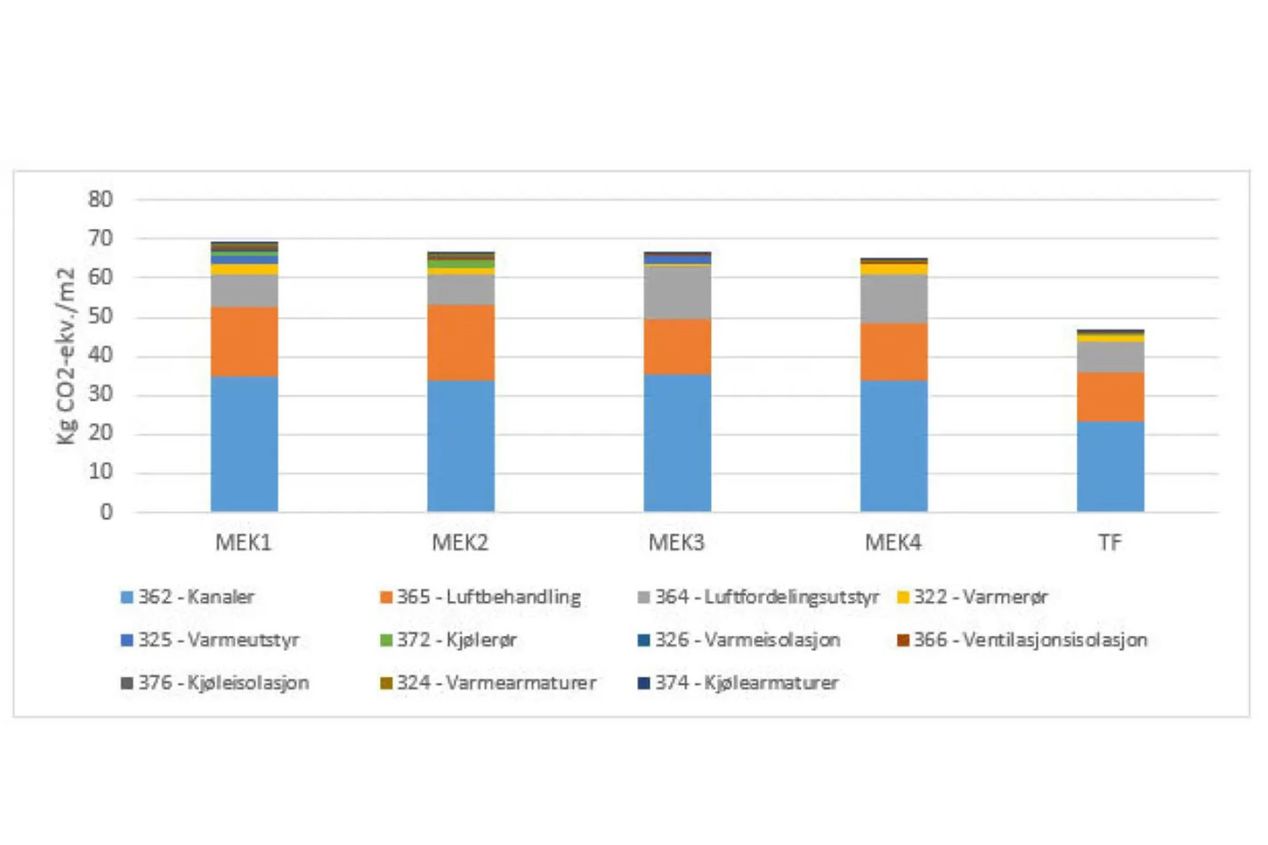

Greenhouse gas emissions from materials for the solutions are shown in Figure 8, which shows that MEK1-4 have emissions of the same order of magnitude, while TF has approximately 30 percent lower emissions than MEK1. The main finding is therefore that the differences between "normal" mechanical solutions are small when looking at fixed emissions from materials. The key to achieving significant emission reductions seems to be to optimize installed capacities in the facilities, as in the TF scenario.

Photo: Multiconsult

The general trends that apply to all solutions are that building component 36 Air handling, with subcategories, accounts for approximately 90-95 percent of the emissions, and 362 Ducts alone accounts for approximately 50 percent of the total emissions. Next come 365 Air handling (units) and 364 Air distribution equipment (valves and baffles) with significant contributions. In contrast to our initial studies, radiators and separate heating systems do not have such a significant impact.

Energy use must be included in overall assessments

Although reduced material use may be most important today, a more holistic life cycle perspective must be considered. Throughout the life of a building, emissions related to energy use play a significant role in the overall climate impact. Emissions are affected by the energy needs of the solutions, the energy products included, and the emission intensity of energy production at the supplier. The distribution between fixed emissions and operational emissions is usually asymmetrically distributed over the lifetime of a building, and the uncertainty associated with the emission intensity of future energy production is significant. To avoid suboptimization and problem shifting, all solutions should be assessed holistically as far as possible, with emphasis on both fixed and operational emissions. Establishing new energy sources is also problematic in terms of land use, nature and political considerations.

Greenhouse gas emissions for materials and energy are shown in Figure 9. The result shows that MEK1, 2 and 4 are of the same order of magnitude, while MEK3 has significantly higher emissions. The increased emissions for MEK3 are caused by a large proportion of the energy use being direct-acting electricity. TF results in a 23 percent reduction in total greenhouse gas emissions compared to MEK1. The main findings, when energy use in operation is included, are that increased use of electric heating results in significantly increased emissions, and that scaling down the solution results in a significant reduction. The choice of air conditioning solution is otherwise of little importance.

Photo: Multiconsult

Adaptability sets the solutions apart

The scaled-down air conditioning solution TF provides lower greenhouse gas emissions in the accounts, both related to material use and energy use in operation. Reducing material use is one of the safest measures that can be taken to cut greenhouse gas emissions, which also has a quick effect. Future emissions are more uncertain, and the results are particularly sensitive to replacements (B4), which depend on the service life of the components, and energy use in operation (B6), which is affected by developments in the energy mix and changes in calculation methods. One of the main reasons why technical installations are often replaced is changes in the use of buildings. For example, when changing tenants in office buildings today, it is not uncommon for entire floors to be cleared to the ground. A strategy to prevent this from happening in the future is to install solutions that can withstand changed use and room layout – often called adaptability.

The MEK 4 and 5 solutions contain underfloor heating and cooling, which limits the possibility of changing the room layout and shifting heating and cooling needs. The TF solution also contains centrally located pre-exhaustion valves, which require that no obstacles are placed in the way of the air spreading out into the room. TF therefore places significant limitations on future changes and the establishment of new rooms. On the one hand, it is obvious that TF provides reduced environmental impact in the current situation, but on the other hand, a more change-friendly solution can last longer. Investments in materials and kroner today, which within a certain probability range provide future gains, are more uncertain measures than reduced material use. However, if done correctly and the effect is large enough, it can be worthwhile.

The issue has not been explored to a large extent today, and the current industry standard for greenhouse gas calculations is not sufficient. Because of this, it is difficult to conclude unequivocally which strategy is best, and further research is therefore needed before this can be fully answered.

What about hybrid ventilation?

In the more extensive work behind this article, several hybrid solutions have also been studied. In these, mechanical ventilation only accounts for a portion of the ventilation. Compared to the mechanical solutions presented in this article, hybrid ventilation provides savings in greenhouse gas emissions. However, for such solutions, there are also greater variations in indoor climate and a number of other factors that affect the relevance and possibility of scaling and use. These solutions and findings have not been the focus of Green HVAC, but will be presented in a separate report from the project R&D Hybrids.

Downscaling is the surest way to cut emissions, but the future is uncertain

Early studies in Green HVAC indicated that it was possible to achieve large greenhouse gas savings by choosing the right air conditioning solutions, without reducing the capacity of the facilities. However, the studies were limited to a section of one floor, and did not include main routes of pipes and ducts, units, or energy requirements. The study that has now been carried out is more comprehensive, and includes an entire floor with all necessary infrastructure, with the exception of the energy center itself. The picture has changed, and there appears to be little difference related to the choice of air conditioning solution. The results, however, show that increased use of electric heat emitters is negative for the climate, and that downscaling the HVAC systems provides a gain.

The fact that reducing emissions is now urgent is a good argument for using downscaling solutions. At the same time, there is too little knowledge related to adaptability and future replacements. It should therefore be considered whether facilities can be scaled down, while assessments of adaptability and future use are made in each individual project.

The authors would like to clarify that the study was conducted on a single theoretical office building, in a specific climate, with a specific set of products. The results should therefore be used with caution and can only be applied to a limited extent to other buildings, and not to other building categories or climate locations. That said, the study is thoroughly researched and represents common practice and products, and therefore provides clear indications for the path forward towards lower greenhouse gas emissions from air conditioning in buildings.

Further information about Green HVAC

Green Plumbing is an Innovation Project in the business sector, supported by the Research Council of Norway. The project was carried out in the period September 2021 to March 2025.

Project objectives: Building competence, developing new services and sharing knowledge. Showing the way to a 50% reduction in greenhouse gas emissions from HVAC installations in model projects

The project manager is Multiconsult. Partners in the project are Höegh Eiendom, GK, Armaturjonsson, Swegon, KLP Eiendom and Pipelife. R&D supplier is OsloMet. The reference group consists of VKE and FutureBuilt.