Choice of fire extinguishing system affects greenhouse gas emissions

HVAC - The hidden climate giant

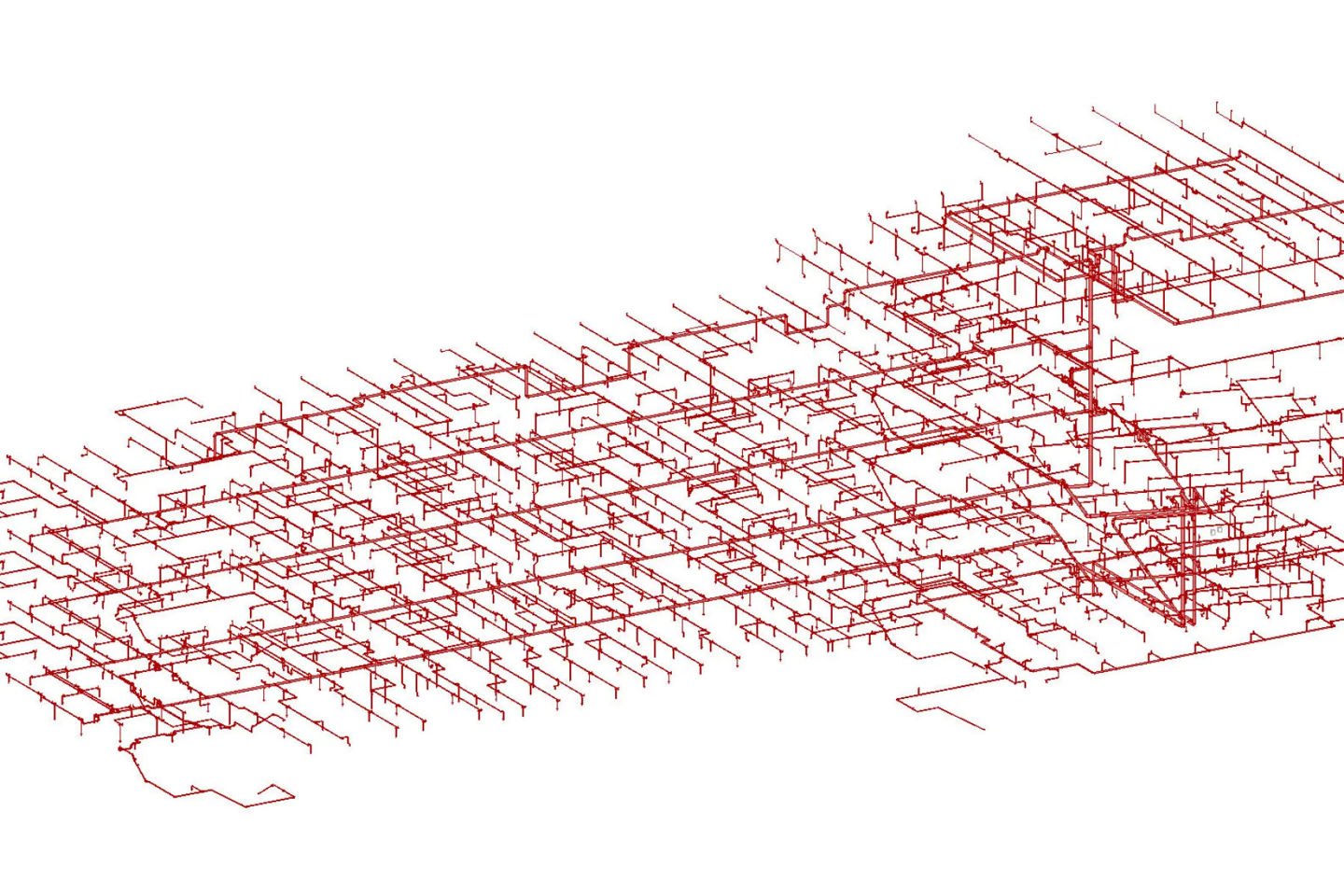

The figure shows the sprinkler system at Voldsløkka School.

Photo: Multiconsult

Suitability must be assessed in each individual case

Fire extinguishing systems are now common for most building categories, with the exception of small houses. Sprinkler systems are the most commonly used solution, but there are several different system types that can be used to solve many of the application areas.

The study conducted shows that there are great opportunities to reduce greenhouse gas emissions when choosing a fire extinguishing solution. However, it is important to clarify that it is the safety aspect that should be the leading factor when choosing solutions, and suitability must be assessed by experts in each individual project.

Material use in fire extinguishing systems accounts for significant greenhouse gas emissions

Studies conducted in the Green Plumbing research project show that HVAC installations account for 20-40 percent of the greenhouse gas load associated with material use in new buildings. In all studies conducted in the project, the largest HVAC technical greenhouse gas contributions come from the building components ventilation and fire extinguishing systems, and from the individual components ventilation units, ducts and sprinkler pipes. Since fire extinguishing systems make a large contribution, it is timely to explore the scope for optimizing the installations.

The research project aims to shed light on the consequences of the choice of fire extinguishing solution for greenhouse gas impacts, so that this can be included as a factor in overall assessments. The topic has been explored in a separate study in Grønn VVS, in close collaboration with Multiconsult's fire extinguishing system group. The main findings are summarized in this article.

The report primarily studies greenhouse gas emissions from materials when installing fire extinguishing systems, but it also includes an assessment of water volume, weight and cost. To enable comparison, four different solutions have been designed, with an assumed equivalent fire extinguishing function in the described object. The focus of the work is to compare technical solutions. Therefore, brands and supplier names have been omitted.

Four different extinguishing solutions for offices

The work has studied four different typologies for automatic fire extinguishing in a typical office building:

- Conventional sprinkler (KS), sprinkler heads placed with conservative coverage area and with calculations based on estimated dimensions taken from tables for pre-calculation. The typology represents a widely used design practice and is considered the most historically used solution.

- Optimized sprinkler (OS), with fewer sprinkler heads with extended coverage, reduced pipe network and optimized pipe dimensions. The typology represents best industry practice for sprinkler systems.

- Low-pressure water mist (LV), with optimized utilization of coverage areas and pipe dimensions. For LV, a pump center is used. The pipe dimensions are smaller than for KS and OS.

- High-pressure water mist (HV), with optimized utilization of coverage areas and pipe dimensions. For HV, a more powerful pump center is used than for LV. The solution has the smallest pipe dimensions.

Major differences in material use

The material weight for KS is the largest at 9.7 tons, while for OS it is reduced by 41 percent to 5.8 tons. For the water mist solutions, the weight is significantly lower at 1.3 and 1.7 tons for LV and HV, respectively. HV has higher material use than LV, due to a larger pump center, and little savings for smaller pipe dimensions with thicker material.

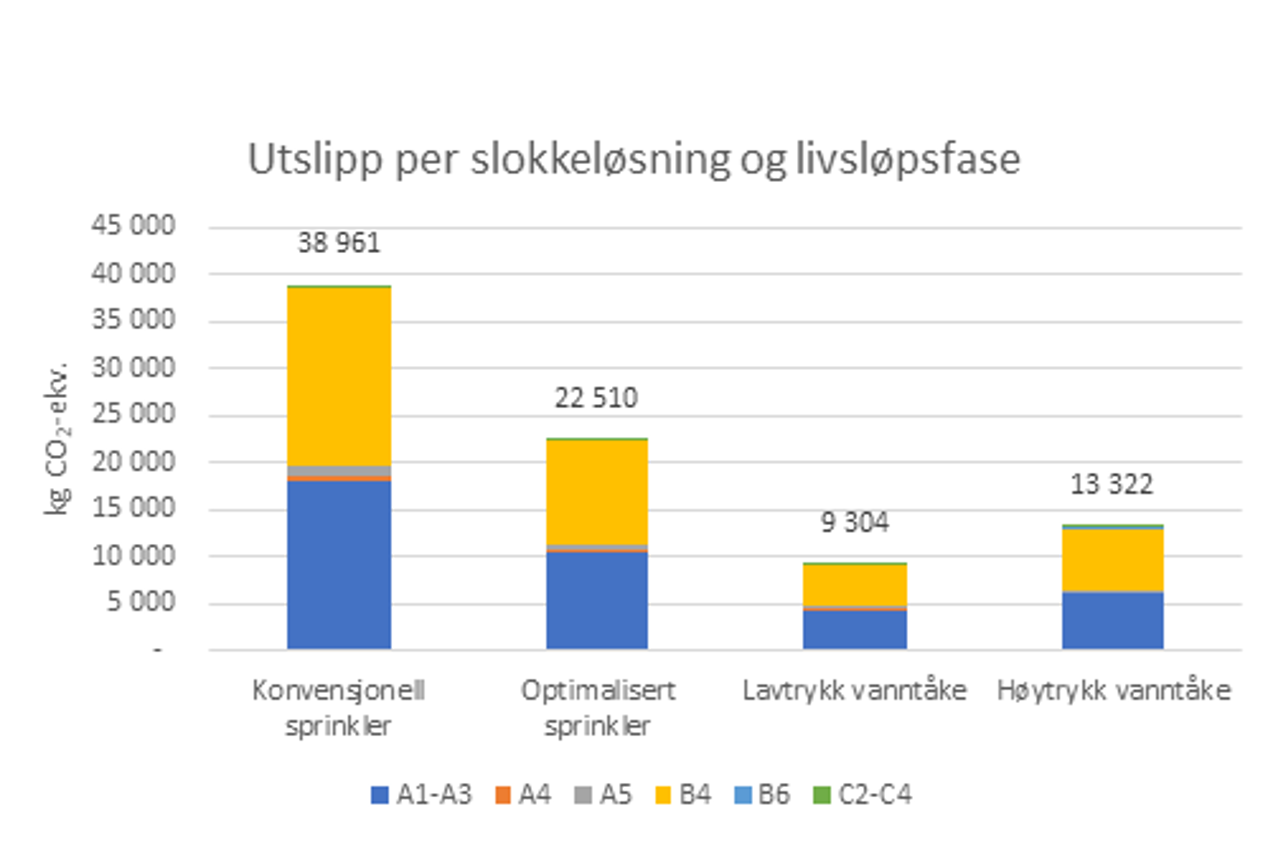

Greenhouse gas emissions can be significantly reduced

For sprinkler solutions, 85-86 percent of greenhouse gas emissions come from pipes. For water mist solutions, equipment in the pump center is of significant importance and accounts for 15 percent for LV and 44 percent for HV.

In total, the greenhouse gas calculations show that KS has the highest emissions of 39 tons of CO2-eq. This amounts to 11.7 kg CO2-eq. per sq m of office. By optimizing sprinklers (OS), a 42 percent emission reduction to 23 tons of CO2-eq. Greenhouse gas emissions for LV are estimated at 9 tons CO2-eq. and thus achieve a further 59 percent reduction compared to OS. Greenhouse gas emissions for HV are estimated at 13 tons CO2-eq. and give a 41 percent reduction compared to OS, but are 43 percent higher than LV.

The typologies have different use characteristics and therefore the transfer value of the results from this must be assessed separately in each individual project case.

Photo: Multiconsult

Production and lifespan have the greatest impact

For all four solutions studied, material production and replacement of materials (life cycle phases A1-A3 and B4) account for approximately 95 percent of greenhouse gas emissions. In order to achieve emission reduction, the strongest focus should therefore be placed on measures that reduce material use, increase lifespan and reuse - measures here can yield rapid gains.

Optimization pays off for the wallet

The cost assessment shows that the transition from KS to OS reduces material and installation costs by 30 percent. Optimization entails increased project costs, but this is of a smaller order of magnitude and therefore provides a net saving. Compared to OS, the water mist solutions entail a cost increase of 49 percent for LV and 120 percent for HV. The most comparable solutions are OS, LV and HV, because they are all optimized. The differences are partly related to the use of pipes and parts with higher material quality for water mist.

Photo: Multiconsult

A challenge for the industry

The results of the study show that pipes in sprinkler systems constitute the largest item for greenhouse gas emissions, while for water mist systems there is a challenge with approvals for various areas of use and that the costs of installation are higher. Innovation work to find pipe types that have lower emissions than those used today, and facilitating the reuse of pipes, could have a major effect on the amount of emissions.

What about the emissions from a real fire?

In order to make a comprehensive greenhouse gas assessment of fire extinguishing systems, reduced or prevented emissions from building fires should also be included. This is a complex task that includes the probability of a fire occurring, the time of the fire, and emissions with and without a fire extinguishing system. We have not been able to include this, but have tried to reduce any impact of this by comparing solutions with equivalent extinguishing effect.

Safety must come first

The study shows how greenhouse gas emissions from materials can be calculated to be included in an overall assessment when choosing a fire extinguishing solution. The results show that there are significant greenhouse gas emissions from fire extinguishing systems and great optimization potential. Nevertheless, it is the safety aspect that should always be the first priority when choosing a solution and suitability must be assessed by experts in each individual project.

Climate challenges force us to think differently

An industry that works with fire safety is by nature somewhat conservative when choosing solutions. But climate change also entails a risk, only on a larger scale. The fire extinguishing industry must therefore, like other parts of society, also think differently in the transition to a sustainable society.

Through the research, it has now been established that there are significant greenhouse gas emissions associated with the use of materials in fire extinguishing systems. In the future, greenhouse gas emissions must therefore be included as a factor when we design fire extinguishing solutions, which in turn may result in changed practices.

Water mist systems have been shown to provide significant greenhouse gas savings, but currently involve some cost increases. There are test standards for water mist systems in many building types, but not all building types and areas of use can be covered with water mist as of today.

Furthermore, the greenhouse gas savings by optimizing sprinkler systems are shown to be significant, and also provide net cost savings. Therefore, it is obvious that all types of extinguishing systems must be optimized for climate considerations, as long as the conditions in the individual project allow it.

Our assessments in full detail

This article is a brief summary of a more in-depth report on the subject, prepared by the R&D project Green Plumbing, which is available for download on the project's website.

Further information about Green HVAC

Green Plumbing is an Innovation Project in the business sector, supported by the Research Council of Norway. The project was carried out in the period September 2021 to March 2025.

Project objectives: Building competence, developing new services and sharing knowledge. Showing the way to a 50% reduction in greenhouse gas emissions from HVAC installations in model projects

The project manager is Multiconsult. Partners in the project are Höegh Eiendom, GK, Armaturjonsson, Swegon, KLP Eiendom and Pipelife. R&D supplier is OsloMet. The reference group consists of VKE and FutureBuilt.